新聞中心

導(dǎo)軌絲杠在使用中出現(xiàn)質(zhì)量不合格的原因

來源:http://baoxianyingxiao.cn/ 日期:2023-07-25 發(fā)布人:

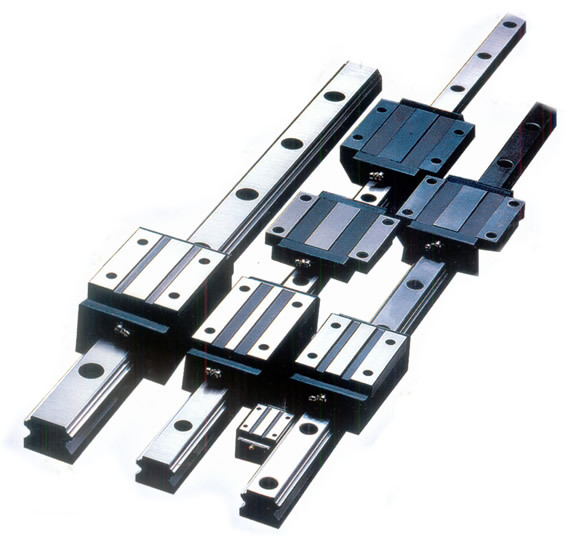

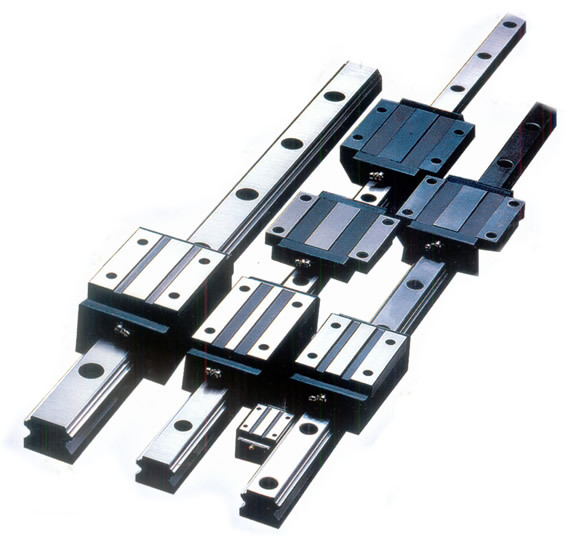

導(dǎo)軌絲杠是一種用于線性運(yùn)動傳動的機(jī)械零件,常用于工業(yè)設(shè)備、機(jī)床和自動化系統(tǒng)中。它由螺紋絲杠和導(dǎo)軌組成,通過轉(zhuǎn)動螺紋絲杠使配套的滑塊在導(dǎo)軌上做直線運(yùn)動。那么導(dǎo)軌絲杠在使用中出現(xiàn)質(zhì)量不合格可能有以下原因:

Guide screw is a kind of Machine element for linear motion transmission, which is commonly used in industrial equipment, machine tools and automation systems. It consists of a threaded screw and a guide rail, which rotates the threaded screw to make the matching slider move in a straight line on the guide rail. So, there may be the following reasons for the unqualified quality of the guide screw during use:

1.材料問題:導(dǎo)軌絲杠的材料質(zhì)量不合格,可能存在含雜質(zhì)、強(qiáng)度不夠或材料硬度差異等問題。

1. Material problem: the material quality of guide screw is unqualified, which may have problems such as impurities, insufficient strength or Hardness difference.

2.制造工藝問題:導(dǎo)軌絲杠的制造過程中出現(xiàn)問題,例如加工不精確、熱處理溫度控制不當(dāng)?shù)龋伎赡軐?dǎo)致質(zhì)量不合格。

2. Manufacturing process issues: Problems during the manufacturing process of guide rail screws, such as inaccurate processing, improper heat treatment temperature control, etc., may lead to unqualified quality.

3.表面質(zhì)量問題:導(dǎo)軌絲杠的表面粗糙度、光潔度不符合要求,或者存在劃痕、磨損等表面缺陷,會影響導(dǎo)軌絲杠的摩擦和運(yùn)動性能。

3. Surface quality issue: The surface roughness and smoothness of the guide screw do not meet the requirements, or there are surface defects such as scratches and wear, which can affect the friction and motion performance of the guide screw.

4.尺寸偏差問題:導(dǎo)軌絲杠的尺寸偏差超過規(guī)定范圍,例如直徑不一致、螺紋間距不準(zhǔn)確等,會導(dǎo)致配合件無法正常運(yùn)動或密封。

4. Size deviation issue: The size deviation of the guide screw exceeds the specified range, such as inconsistent diameter, inaccurate thread spacing, etc., which can cause the mating parts to fail to move or seal normally.

5.配合件問題:導(dǎo)軌絲杠和配套配合件之間的配合不良,例如滾珠軸承、導(dǎo)軌座等,會影響導(dǎo)軌絲杠的精度和穩(wěn)定性。

5. Matching part issue: Poor matching between the guide screw and the matching parts, such as ball bearings, guide seats, etc., can affect the accuracy and stability of the guide screw.

6.磨損和劣化:長時間使用后,導(dǎo)軌絲杠可能會出現(xiàn)磨損、疲勞斷裂等問題,導(dǎo)致質(zhì)量下降。

6. Wear and deterioration: After prolonged use, the guide screw may experience wear, fatigue fracture, and other issues, leading to a decrease in quality.

7.不良環(huán)境影響:使用環(huán)境可能存在腐蝕、高溫、高濕度等因素,對導(dǎo)軌絲杠造成不利影響,導(dǎo)致質(zhì)量問題。

7. Adverse environmental impact: The use environment may have factors such as corrosion, high temperature, and high humidity, which can have adverse effects on the guide screw and lead to quality issues.

以上僅列舉了一些可能導(dǎo)致導(dǎo)軌絲杠質(zhì)量不合格的原因,具體情況還需要根據(jù)實際情況進(jìn)行分析和判斷。如果遇到質(zhì)量不合格的導(dǎo)軌絲杠,建議及時聯(lián)系制造商或供應(yīng)商,進(jìn)行退換貨或維修處理。

The above only lists some possible reasons for the unqualified quality of the guide screw, and the specific situation needs to be analyzed and judged based on the actual situation. If you encounter substandard guide screws, it is recommended to contact the manufacturer or supplier in a timely manner for return, exchange, or repair.

以上就是今天所要講解的內(nèi)容了,相信大家在看完本文的描述之后,能夠?qū)ζ溆幸欢ǖ恼J(rèn)識和了解,希望以上內(nèi)容能幫助到你。另外,若你想要了解更多相關(guān)資訊,可以多多關(guān)注我們的網(wǎng)站動態(tài)http://baoxianyingxiao.cn。

The above is the content to be explained today. I believe that after reading the description in this article, everyone can have a certain understanding and understanding of it. I hope the above content can help you. In addition, if you want to learn more about relevant information, you can pay more attention to our website updates http://baoxianyingxiao.cn .

導(dǎo)軌絲杠:從設(shè)計結(jié)構(gòu)...<>

導(dǎo)軌絲杠:從設(shè)計結(jié)構(gòu)...<> 大型絲杠的性能設(shè)計介...<>

大型絲杠的性能設(shè)計介...<> 梯形絲杠和滾珠絲杠的...<>

梯形絲杠和滾珠絲杠的...<> 滾珠絲桿目前的行業(yè)的...<>

滾珠絲桿目前的行業(yè)的...<> 滾珠絲杠螺母油封更換...<>

滾珠絲杠螺母油封更換...<>

相關(guān):