新聞中心

選擇開料機(jī)應(yīng)該注意哪些細(xì)節(jié)

來源:http://baoxianyingxiao.cn/ 日期:2023-06-15 發(fā)布人:

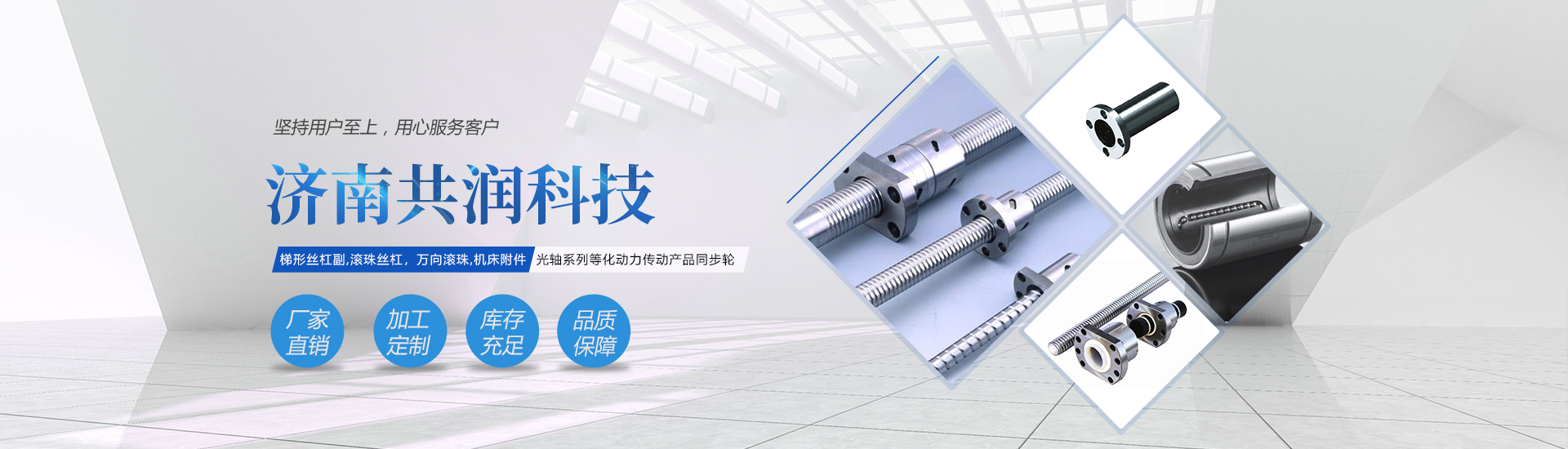

開料機(jī)的主軸

Spindle of the cutting machine

開料機(jī)主軸的大小直接影響到開料機(jī)的加工精度這和選配的開料機(jī)類型及所加工的板材有直接關(guān)系。一般的開料機(jī)建議選擇6kw和4,5kw,足以保證開料機(jī)的加工精度。需要注意的一點(diǎn)開料機(jī)中的加工,一般選用9kw主軸,不僅僅是因?yàn)楸P式換刀加工開料機(jī)加工產(chǎn)品需要大功率主軸,更是因?yàn)樗梢宰詣?dòng)換刀。

The size of the spindle of the cutting machine directly affects the machining accuracy of the cutting machine, which is directly related to the type of cutting machine selected and the processed sheet metal. For general cutting machines, it is recommended to choose 6kw and 4,5kw to ensure the machining accuracy of the cutting machine. It should be noted that the machining center in the cutting machine usually uses a 9kw spindle, not only because the disc type tool change machining center requires a high-power spindle for processing products, but also because it can automatically change tools.

開料機(jī)的電機(jī)

Motor of the cutting machine

普通三工序開料機(jī)、四工序開料機(jī)建議選用雷塞混合伺服或者雷塞純伺服。更高配置的開料機(jī)建議選用進(jìn)口安川伺服電機(jī),穩(wěn)定性更好,使用壽命更長。

It is recommended to choose either a Reiss hybrid servo or a Reiss pure servo for ordinary three process cutting machines and four process cutting machines. For higher configuration cutting machines, it is recommended to use imported Yaskawa servo motors for better stability and longer service life.

開料機(jī)的變頻器

Frequency converter of the cutting machine

于變頻器一般建議選用富凌或者臺(tái)達(dá)變頻為佳。

As for frequency converters, it is generally recommended to choose Fuling or Delta frequency converters.

開料機(jī)驅(qū)動(dòng)

Cutting machine drive

導(dǎo)軌絲杠廠家提醒您,一般什么類型的電機(jī)選用什么類型的驅(qū)動(dòng)。

The manufacturer of the guide rail screw reminds you what type of motor is generally used for driving.

機(jī)床整架

Whole machine tool frame

采用側(cè)掛式重型穩(wěn)定床身。床身更加穩(wěn)定,不易變形,直接影響到開料機(jī)的加工精度。

Adopting a side hung heavy-duty stable bed. The bed is more stable and less prone to deformation, which directly affects the machining accuracy of the cutting machine.

傳動(dòng)方式

Transmission mode

目前開料機(jī)選用多的傳動(dòng)方式:X、Y軸進(jìn)口斜齒條傳動(dòng),Z軸絲杠傳動(dòng)。這樣的傳動(dòng)方式比之全絲杠的傳動(dòng)方式提升了開料機(jī)的運(yùn)行速度和加工精度。

At present, the cutting machine adopts multiple transmission methods: X and Y axis imported helical rack transmission, and Z axis lead screw transmission. This transmission method improves the operating speed and processing accuracy of the cutting machine compared to the full screw transmission method.

導(dǎo)軌

Guide rail

導(dǎo)軌分方軌和圓軌之分,目前開料機(jī)一般都會(huì)選用進(jìn)口方軌配合方軌滑塊,運(yùn)行更穩(wěn)定,加工精度更高。開料機(jī)的普及,讓大家逐漸意識(shí)到在未來板式家具的生產(chǎn)更多是受產(chǎn)品精度、精美程度、多樣性、加工效率等因素。

The guide rails are divided into square rails and circular rails. Currently, the cutting machine generally uses imported square rails with square rail sliders to ensure more stable operation and higher machining accuracy. The popularization of cutting machines has gradually made people realize that in the future, the production of panel furniture will be more influenced by factors such as product accuracy, delicacy, diversity, and processing efficiency.

而開料機(jī)可以很輕松的解決這個(gè)問題,只需幾天時(shí)間的學(xué)習(xí)既可以熟練掌握。并且,開料機(jī)的加工精度,圖案的精美程度也不是人工可以比擬的。開料機(jī)的加工效率更是板式家具行業(yè)的不二之選。您有需求就來我們網(wǎng)站http://baoxianyingxiao.cn咨詢吧!

The cutting machine can easily solve this problem, and it only takes a few days of learning to master proficiently. Moreover, the processing accuracy of the cutting machine and the exquisite degree of the pattern are not comparable to manual labor. The processing efficiency of the cutting machine is the best choice in the panel furniture industry. Come to our website if you have any needs http://baoxianyingxiao.cn Consult!